No products in the basket.

Vehicle Test Centre

Mitie were instructed by the client to look at cost savings and reduction of energy consumption across the occupied estate. One key area was a reduction in heating costs and Herschel were approached to see how Far Infrared electric heating could achieve this and provide a more efficient and effective way of heating four areas. Mitie and the Client are now monitoring the overall energy savings and reduced consumption and ratifying these in accordance with International Performance Measurement and Verification Protocol (IPMVP). This provides best practice techniques for verifying results of energy efficiency, water efficiency, and renewable energy projects in commercial and industrial facilities. Herschel Far Infrared products are now being considered for a number of other projects.Improved Energy Consumption & Carbon Emissions

Site: Warehouse Unit in North West England, built 1989 circa 46,000 sq ft.

Why Involve Herschel?

- Existing heating was not zoned or controlled and required large amounts of air to be heated for significant periods of time

- An inefficient system meant significant heating cost

- Areas that needed heating could not be separated and zoned from other space

- Open warehouse doors and air-flow was resulting in significant heat losses from existing heating system

Existing Heating

| Area | Heater Type | Heater Number | Heater Output (kW) |

| MOT Bay | Gas heater – 23.50kW | 1 | 23.5 |

| Main Store | Gas heater – 23.50kW | 2 | 47 |

| Sub-tenant unit | Gas heater – 48.00kW | 4 | 192 |

| Parts Store | Electric convector heaters – 2kW | 3 | 6 |

| Total | 10 | 268.50 kW |

The Herschel Infrared Solution

- Zone heating more effectively with Infrared electric heaters in the areas needed and where people are working

- Offer directional heat for staff and also heat the fabric of the building rather than the air

- Combine the heaters with TS3 pre-programmable push button timers (on for 30 mins when activated) only used when required

- Estimated heating time of 5.5hrs per day provided by the client and reflected below

- Improved efficiency and reduction in total energy consumed (see estimates below)

- Enable the building to retain the heat for longer and radiate back

- Improved comfort levels for staff

- No maintenance or servicing of the infrared heaters after installation

- Less air movement, reduced movement of dust and air borne particles

| Area |

Herschel Infrared Heaters Installed |

Heater Numbers | Heater Output (kW) |

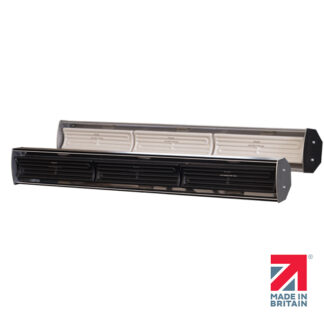

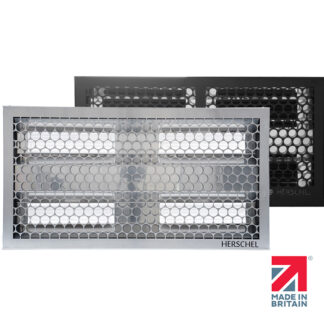

| MOT Bay | Advantage IR2 – 1.30kW | 4 | 5.20 |

| Main Store | Advantage IRP4 – 2.60kWAdvantage IR3 – 1.95kW | 64 | 15.67.80 |

| Sub-tenant unit | Advantage IRP4 – 2.60kWAdvantage IR3 – 1.95kWAdvantage IR2 – 1.30kW | 311 | 7.801.951.30 |

| Parts Store | Advantage IR3 – 1.95kWAdvantage IR3 – 1.30kW | 21 | 3.901.30 |

| Total | 22 | 44.85 |

Energy Consumption and Financial Summary

Current consumption figures and unit rate based on information from Mitie and Client. Consumption estimates using Herschel Infrared heaters are pre-install estimates. These figures do not include any annual servicing and safety testing costs for the existing gas heaters.

| Annual Consumption | Current | Estimated Consumption Herschel Electric Infrared | Estimated Annual Savings | % Saving** |

| Consumption | Gas – 285,271 kW/hElectric – 8,832 kW/hTotal – 294,103 kW/h | 28,275 kW/hTotal – 28,275 kW/h(estimate of 5.5hrs per zone per day) | 265,828 kW/h | 90% |

| Costs * | £10,894(Unit price assumedGas – £0.0347 per kW/hElectric £0.1127 per kW/h) | £3,187(Unit price assumed £0.1127 per kW/h) | £7,707(after paying for supply and install | 71% |

| Payback using Herschel Solution | |

| Estimated Payback Period for supply and install cost | 3.63 yrs (c.43.60 months) |

*All figures exclusive of VAT ** % Savings rounded

| % Reduction in Consumption *** | Current | Herschel | Savings pa | % Saving** |

| Total Emissions CO2 (Kg)

Equivalent toCarbon Emissions (Kg) |

57,132

15,597 |

13,975

3,815 |

43,157

11,782 |

76%

76% |

*** (Using Carbon Calculator www.carbon-calculator.org.uk)

Further Analysis

Mitie and the Client are now monitoring the overall energy savings and reduced consumption and ratifying these in accordance with International Performance Measurement and Verification Protocol (IPMVP). This provides best practice techniques for verifying results of energy efficiency, water efficiency, and renewable energy projects in commercial and industrial facilities.

Herschel Far Infrared products are now being considered for a number of other projects.